Home » Applications » Variable frequency drive on Booster Pumps

Variable frequency drive on Booster Pumps

Pressure booster pumps essentially add pressure to a commercial buildings water supply at times when the water mains pressure is not sufficient. Most multistory apartment complexes, hotels, etc, require pressure booster pumps to supply adequate pressure to terminal units such as showers and bathrooms.

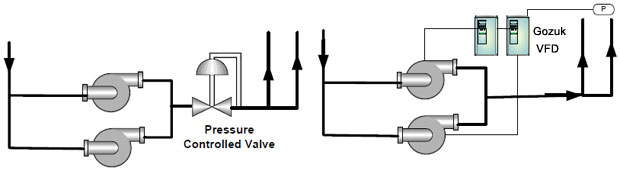

The pressure booster pumps need to be sized to maintain the design pressure while experiencing the maximum expected flow at the lowest suction pressure to the pump. A pressure control valve is used to balance the system and maintain the desired pressure in the system as the flow rate decreases or suction pressure varies to avoid over pressurization and control problems. In instances where the flow requirements vary significantly, multiple pumps are placed in parallel. As water consumption changes, additional pumps are staged on or off to maintain the pressure.

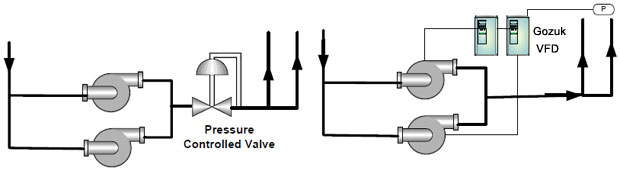

VFD can be added to pressure booster pumps as an alternative to using pressure control valves. This saves the energy and eliminates its cost and maintenance. The vfd savings can amount to 20% or more, simply due to the safety factor used during the design of the system. If the suction pressure of the pump varies, the over-sizing of the pump required to handle the lowest suction pressure does not penalize the installation, when the suction pressure increases.

Control Considerations

The location of the pressure sensor is important. In the relatively small pressure booster pumping systems found in commercial buildings, it is important to place the pressure sensor at the furthest possible location.

When the variable frequency drive booster pump system becomes too large for one sensor, multiple sensors can be used, each placed in a critical area of the system. Where this is not possible, different set points can be established depending on the number of pumps operating.

The pressure booster pumps need to be sized to maintain the design pressure while experiencing the maximum expected flow at the lowest suction pressure to the pump. A pressure control valve is used to balance the system and maintain the desired pressure in the system as the flow rate decreases or suction pressure varies to avoid over pressurization and control problems. In instances where the flow requirements vary significantly, multiple pumps are placed in parallel. As water consumption changes, additional pumps are staged on or off to maintain the pressure.

VFD can be added to pressure booster pumps as an alternative to using pressure control valves. This saves the energy and eliminates its cost and maintenance. The vfd savings can amount to 20% or more, simply due to the safety factor used during the design of the system. If the suction pressure of the pump varies, the over-sizing of the pump required to handle the lowest suction pressure does not penalize the installation, when the suction pressure increases.

Control Considerations

The location of the pressure sensor is important. In the relatively small pressure booster pumping systems found in commercial buildings, it is important to place the pressure sensor at the furthest possible location.

When the variable frequency drive booster pump system becomes too large for one sensor, multiple sensors can be used, each placed in a critical area of the system. Where this is not possible, different set points can be established depending on the number of pumps operating.

Post a Comment:

You may also like:

Featured Articles

Variable frequency drive application ...

Variable Frequency Drive (VFD) can be used in lots of fields. Variable frequency drives are widely used to control the speed of ...

Variable Frequency Drive (VFD) can be used in lots of fields. Variable frequency drives are widely used to control the speed of ...

Variable Frequency Drive (VFD) can be used in lots of fields. Variable frequency drives are widely used to control the speed of ...

Variable Frequency Drive (VFD) can be used in lots of fields. Variable frequency drives are widely used to control the speed of ...

VFD manufacturers

Thank you.