Home » Case study » Stop & start problem in remote mode from DCS

Stop & start problem in remote mode from DCS

When I start the motor one by one from DCS than it run properly and it's load can very And when I start the motors of heavy load about 20 to 30 together and then it's suddenly OFF And after that one - second it's automatically again ON and this problem is generate some time in 30-minute, sometime -40 and sometime in -25 minute BUT when I start all these same motors from local (from MCC FEEDER) than it don't give any problem and after that I start these only mcc feeder(without on MOTOR in field ) from DCS than it do not give any problem.

The motors three phase and squirrel cage only you can allow some starts per hour, for example a motor of 100HP@1800RPM only allow 2 start on cold and 10 on Hot per hour. However is possible to increase this condition using Soft Starter and Variable Frequency Drive (VFD). With soft starter you can obtain a 30% more in this allow starts, so you using VFD this trend to infinite.

Also you need review, if the brake of motors can inject energy to power network in this case you need brake resistor or using VFD with reinject the power to network.

But if you need more control you should review motion control and use servomotors on Siemens the family Sinamics and Allen Bradley the family Kinetix.

For remote control existing many alternatives of communication, for example profinet, profibus DP, AS-i (if you use contactors), etc. However if you use a communication of high level you can use gateway.

If the motors are stopping, they must be getting stop command from somewhere. For testing, choose the least important motors of those, and then disconnect the DCS stop command in the MCC and then run the motor in the DCS mode. If you still get the problem, it is not related to the DCS.

The motors three phase and squirrel cage only you can allow some starts per hour, for example a motor of 100HP@1800RPM only allow 2 start on cold and 10 on Hot per hour. However is possible to increase this condition using Soft Starter and Variable Frequency Drive (VFD). With soft starter you can obtain a 30% more in this allow starts, so you using VFD this trend to infinite.

Also you need review, if the brake of motors can inject energy to power network in this case you need brake resistor or using VFD with reinject the power to network.

But if you need more control you should review motion control and use servomotors on Siemens the family Sinamics and Allen Bradley the family Kinetix.

For remote control existing many alternatives of communication, for example profinet, profibus DP, AS-i (if you use contactors), etc. However if you use a communication of high level you can use gateway.

If the motors are stopping, they must be getting stop command from somewhere. For testing, choose the least important motors of those, and then disconnect the DCS stop command in the MCC and then run the motor in the DCS mode. If you still get the problem, it is not related to the DCS.

vfd will run in local but not remote

Post a Comment:

You may also like:

Featured Articles

Variable frequency drive energy ...

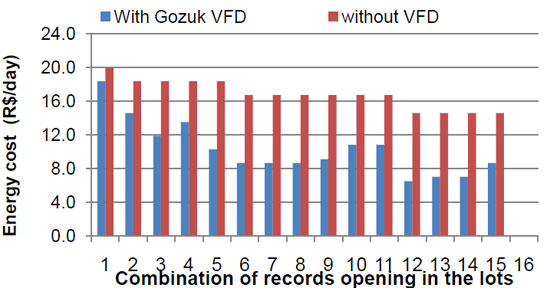

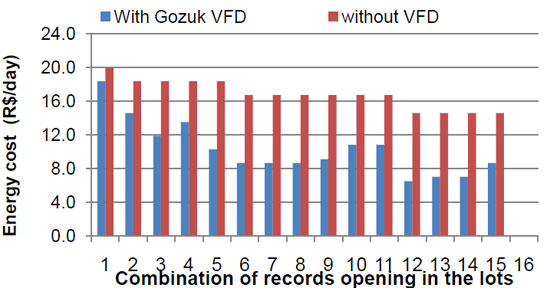

Notes that for the combinations where we had the same number of opened records, the power suffers no change, but when it is used ...

Notes that for the combinations where we had the same number of opened records, the power suffers no change, but when it is used ...

Notes that for the combinations where we had the same number of opened records, the power suffers no change, but when it is used ...

Notes that for the combinations where we had the same number of opened records, the power suffers no change, but when it is used ...Variable frequency drive on Cooling ...

We are working on a study related to Cooling Towers. We want to decrease cooling water supply temperature going to steam ...

We are working on a study related to Cooling Towers. We want to decrease cooling water supply temperature going to steam ...

We are working on a study related to Cooling Towers. We want to decrease cooling water supply temperature going to steam ...

We are working on a study related to Cooling Towers. We want to decrease cooling water supply temperature going to steam ...VFD in China plantation irrigation ...

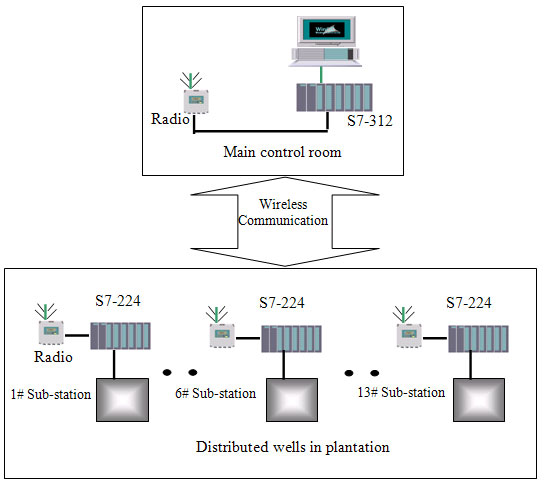

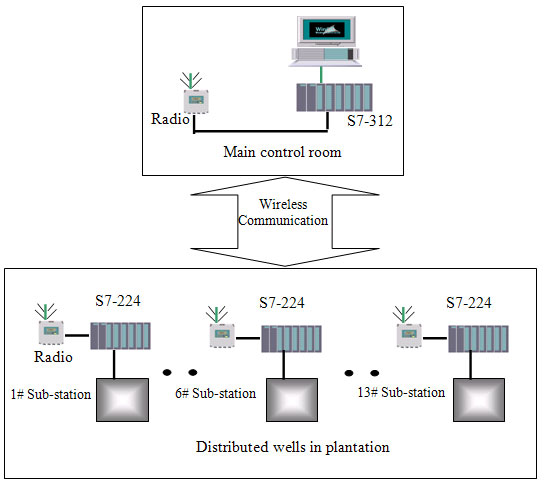

This article have a study of the wireless group control system with variable frequency drive (VFD) applied in a Chinese ...

This article have a study of the wireless group control system with variable frequency drive (VFD) applied in a Chinese ...

This article have a study of the wireless group control system with variable frequency drive (VFD) applied in a Chinese ...

This article have a study of the wireless group control system with variable frequency drive (VFD) applied in a Chinese ...VFD for pumps in variable flow water ...

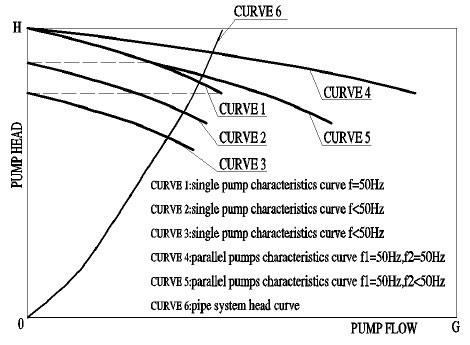

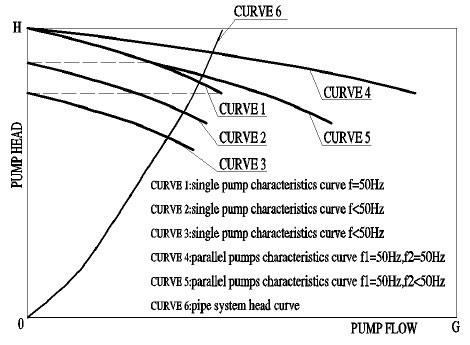

Variable flow water system has played an important role in the field of energy saving with the VFD widely used in practical ...

Variable flow water system has played an important role in the field of energy saving with the VFD widely used in practical ...

Variable flow water system has played an important role in the field of energy saving with the VFD widely used in practical ...

Variable flow water system has played an important role in the field of energy saving with the VFD widely used in practical ...

VFD manufacturers

2. the remote stop/start bits are somehow tied to some 'fuzzy' logic.

find out what process interlocks are used to enable the the signal to engage your drives

3. also check the assignments of your remote stop/start bit addresses,it is possible you may have duplication somewhere.