Home » Case study » One VFD control 3 compressors

One VFD control 3 compressors

Refrigeration compressors, air compressors or gas compressors? Irrespective of which type, the best solution is to have 3 individual variable frequency drive (VFD) running the compressor. These can be started in sequence to minimize power surge. A more economical solution would be to use a single VFD for startup and modulation of a compressor. When this compressor runs to full speed, a bypass contactor kicks in and the VFD can be switched over to a second compressor and then the 3rd when all compressors are running. For added reliability, it may be possible to add a standby VFD. I don't see any advantage of using a single large variable frequency drive for 3 compressors other than the need to synchronize them. Is there such requirement???

Why do have 3 compressors? I think operational requirement is:

Running ==> 2 Nos.

Standby ==> 1 Nos.

Are these centrifugal compressors or positive displacement ones.

Are these compressor outputs connected to a common header?

Any way best and most efficient way to run compressor is to use individual drives unless by mistake you have bought an oversized power stack.

Running ==> 2 Nos.

Standby ==> 1 Nos.

Are these centrifugal compressors or positive displacement ones.

Are these compressor outputs connected to a common header?

Any way best and most efficient way to run compressor is to use individual drives unless by mistake you have bought an oversized power stack.

it is better consult the manufacture of compressors before installation of the VFD,they should support or other wise there may be continuous problems of mechanical seals and some parts wear & tear.and then go three individual drive & keep the system healthy.

A well thought out and practical approach to offer the correct solution. I sometimes wonder if engineers are under pressure to save money but lose sight of the longer term implications of machine life and safety. Stop trying to save a couple of bucks and do it right guys. Actually management puts a lot of pressure to save money on every aspect. And in case of utility section they put a lot of pressure. But in long term vision it doesn't save money as later on we have to spend on maintenance. So its better to spend some extra bucks initially.

Post a Comment:

You may also like:

Featured Articles

Variable frequency drive energy ...

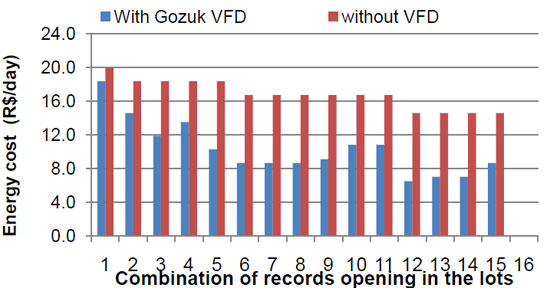

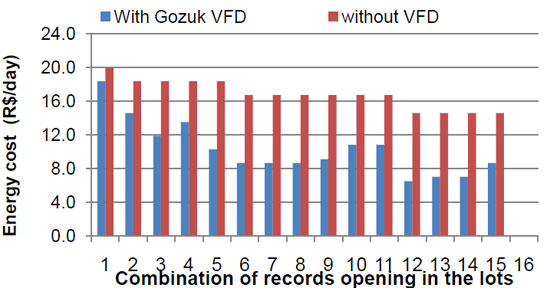

Notes that for the combinations where we had the same number of opened records, the power suffers no change, but when it is used ...

Notes that for the combinations where we had the same number of opened records, the power suffers no change, but when it is used ...

Notes that for the combinations where we had the same number of opened records, the power suffers no change, but when it is used ...

Notes that for the combinations where we had the same number of opened records, the power suffers no change, but when it is used ...Variable frequency drive on Cooling ...

We are working on a study related to Cooling Towers. We want to decrease cooling water supply temperature going to steam ...

We are working on a study related to Cooling Towers. We want to decrease cooling water supply temperature going to steam ...

We are working on a study related to Cooling Towers. We want to decrease cooling water supply temperature going to steam ...

We are working on a study related to Cooling Towers. We want to decrease cooling water supply temperature going to steam ...VFD in China plantation irrigation ...

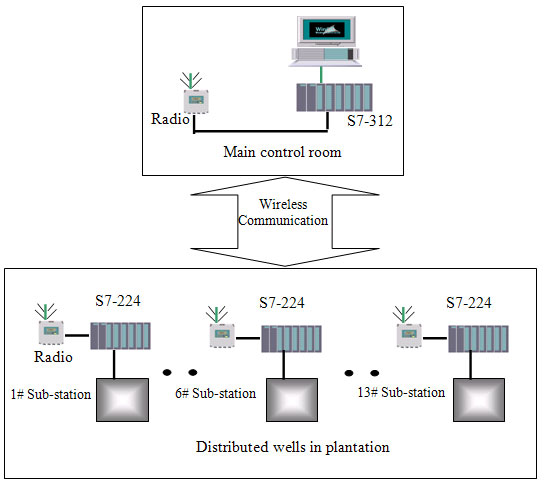

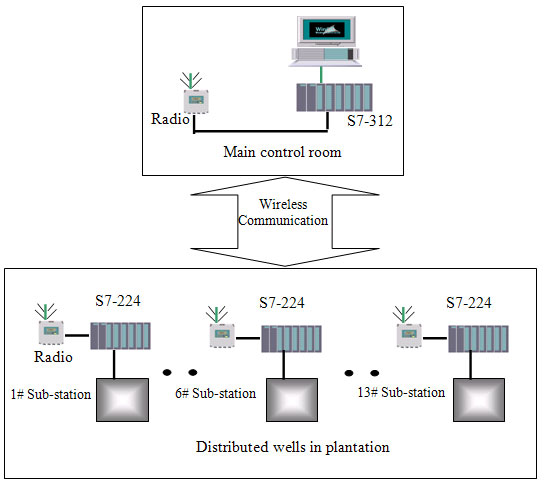

This article have a study of the wireless group control system with variable frequency drive (VFD) applied in a Chinese ...

This article have a study of the wireless group control system with variable frequency drive (VFD) applied in a Chinese ...

This article have a study of the wireless group control system with variable frequency drive (VFD) applied in a Chinese ...

This article have a study of the wireless group control system with variable frequency drive (VFD) applied in a Chinese ...VFD for pumps in variable flow water ...

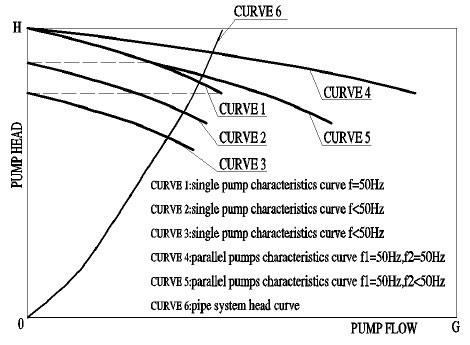

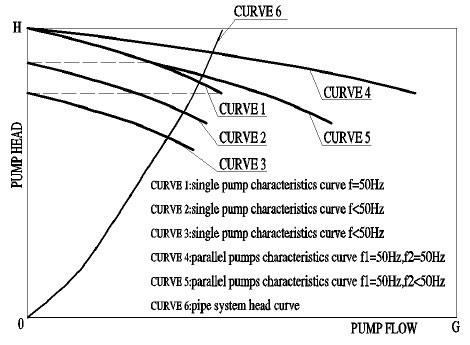

Variable flow water system has played an important role in the field of energy saving with the VFD widely used in practical ...

Variable flow water system has played an important role in the field of energy saving with the VFD widely used in practical ...

Variable flow water system has played an important role in the field of energy saving with the VFD widely used in practical ...

Variable flow water system has played an important role in the field of energy saving with the VFD widely used in practical ...

VFD manufacturers

But! here's a question, why don't you just do this:

Keep 2 of them with star/delta

By 1 VFD

Only 2 compressors work at a time, one S/D and one VFD

The S/D keeps full power all the time and the VFD acts like a "jokey pump" that varies the speed as it is needed.

Considering that 2 are enough to satisfy the facility needs.