Home » Single Phase to Three Phase VFD » 1HP VFD, 50Hz/60Hz 220V single phase input

1HP VFD, 50Hz/60Hz 220V single phase input

VFD Capacity: 1HP (0.75kW)

VFD Capacity: 1HP (0.75kW)Input voltage: 220V, 230V, 240V AC ±15% single phase

Input Frequency: 50Hz or 60Hz

Output voltage: 0 - input voltage three phase

Output Frequency: 0 Hz - 400 Hz (maximum)

Rated current: 4.7 amps

Dimension: 141.5 x 85 x 126 mm

Weight: 1.5 kg

Control mode: V/F control

Speed control accuracy: ±0.5% of rating synchronous speed

Overload capacity: 150% rated current for 1 minute

Analog terminal: 4-20mA or 0-10V

IP grade: IP20

The most common applications of 1hp VFDs are Fans & Pumps, just like larger horsepower VFDs, it changes the power line input of single phase 60Hz/50Hz into variable frequency to feed the 3 phase motor, thus reducing the 3 phase motor speed and electricity consumption. A pressure sensor (connect to the 1 hp VFD) senses the pressure and sends a message to the variable frequency drive. As the demand increases, the pressure sensor will detect the drop in pressure and increase the VFD's frequency in order to increase the motor speed to maintain the pre-set pressure. In the case of 380V 3 phase variable frequency drive, multiple pumps can be controlled by a single VFD, the variable frequency drive inter connected to communicate with each other. Therefore, if one smaller pump can not cope with the water demand, the second pump will power on automatically. As the demand decreases, the pumps will shut off one by one which can have significant savings on electricity.

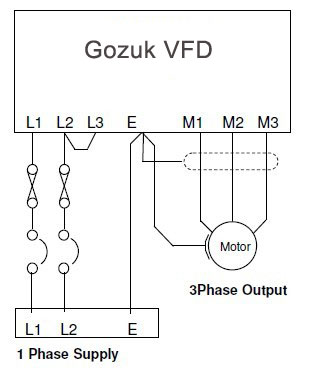

VFD installation

The installation of VFD is simple as shown.

Speed control can be manually using the controls provided or remote speed potentiometer. A Pressure control system can be easily achieved using the variable frequency drive internal PID control and an external pressure sensor.

You may also like:

Featured Articles

Non-Enclosure Variable Frequency Drive ...

No enclosure (cover), reducing installation space and cost effective. Widely used in All-In-One control cabinet. Keep the same ...

No enclosure (cover), reducing installation space and cost effective. Widely used in All-In-One control cabinet. Keep the same ...

No enclosure (cover), reducing installation space and cost effective. Widely used in All-In-One control cabinet. Keep the same ...

No enclosure (cover), reducing installation space and cost effective. Widely used in All-In-One control cabinet. Keep the same ...

VFD manufacturers